- Overview

- Product Description

- Product Parameters

- Application

- Detailed Photos

- Our Advantages

- FAQ

Basic Info.

Product Description

Product Description

Product Description

One-Stop Service to ensure superior quality.

One-Stop Service to ensure superior quality. All of our technicians are trained engineers and know all of the EAF, Ladle Furnace and Foundry applications.

We offer an all-round support to the customers. Check and analyse the customers' furnace conditions in order to achieve an optimal performance of the graphite electrodes and a decrease of the specific electrode consumption.

We also offer other services including train employees,performance analysis,storage in our warehouses,

inspection of accessories, and monitoring the furnace.

| Item | Unit | Graphite Electrode | ||||

| RP(mm) | HP(mm) | UHP(mm) | ||||

| φ100-φ600 | φ100-φ800 | φ200-φ500 | φ550-φ800 | |||

| Resistivity | Electrode | μΩm | 7.0-10.0 | 5.8-6.6 | 4.8-5.8 | 4.6-5.8 |

| Nipple | 4.0-4.5 | 3.5-4.0 | 3.5-4.0 | 3.5-4.0 | ||

| Modulus of Rupture | Electrode | Mpa | 8.0-10.0 | 10.0-13.0 | 10.0-14.0 | 10.0-14.0 |

| Nipple | 19.0-22.0 | 20.0-23.0 | 20.0-24.0 | 22.0-26.0 | ||

| Young's Modulus | Electrode | Gpa | 7.0-9.3 | 8.0-12.0 | 9.0-13.0 | 10.0-14.0 |

| Nipple | 12.0-14.0 | 14.0-16.0 | 15.0-18.0 | 16.0-19.0 | ||

| Bulk Density | Electrode | g/cm3 | 1.53-1.56 | 1.64-1.68 | 1.68-1.74 | 1.68-1.74 |

| Nipple | 1.70-1.74 | 1.75-1.80 | 1.78-1.82 | 1.78-1.84 | ||

| CTE (100-600ºC) | Electrode | 10-6/ºC | 2.2-2.6 | 1.6-1.9 | 1.1-1.4 | 1.1-1.4 |

| Nipple | 2.0-2.5 | 1.1-1.4 | 0.9-1.2 | 0.9-1.2 | ||

| Ash | % | 0.5 | 0.2 | 0.3 | 0.3 | |

| Send inquiry to get fast quote ( Betty: 0086 # 136* 8382* 1762 ) | ||||||

| Nominal Diameter | Actual Diameter | Nominal Length(mm) | ||

| mm | Inch | Max(mm) | Min(mm) | |

| 75 | 3 | 78 | 73 | 1000 |

| 100 | 4 | 103 | 98 | 1200 |

| 150 | 6 | 154 | 149 | 1500-1800 |

| 200 | 8 | 205 | 200 | 1500-1800 |

| 225 | 9 | 230 | 225 | 1500-2100 |

| 250 | 10 | 256 | 251 | 1500-2100 |

| 300 | 12 | 307 | 302 | 1500-2100 |

| 350 | 14 | 357 | 352 | 1500-2400 |

| 400 | 16 | 409 | 403 | 1500-2400 |

| 450 | 18 | 460 | 454 | 1500-2400 |

| 500 | 20 | 511 | 505 | 1800-2700 |

| 550 | 22 | 562 | 556 | 1800-2700 |

| 600 | 24 | 613 | 607 | 2100-2700 |

| 650 | 26 | 663 | 657 | 2100-2700 |

| 700 | 28 | 714 | 708 | 2100-2700 |

| 750 | 30 | 765 | 759 | 2400-2700 |

| 800 | 32 | 816 | 810 | 2400-2700 |

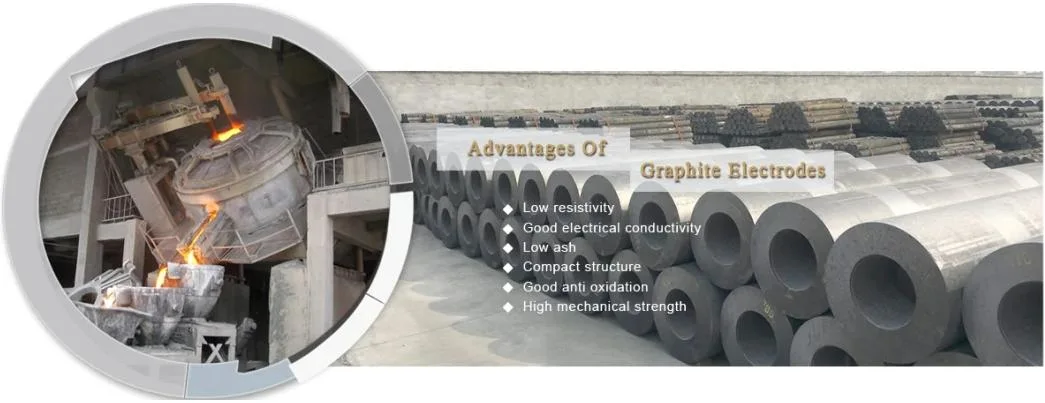

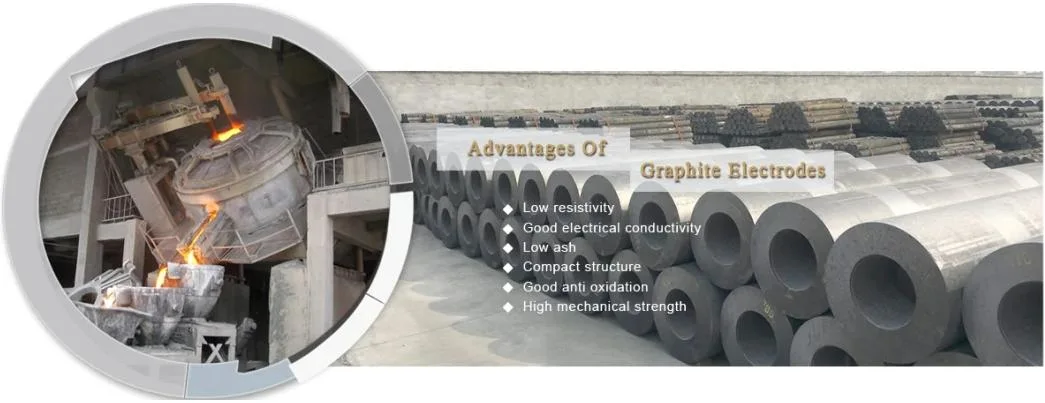

| Application 1. Electric arc steelmaking furnace. 2. Ladle arc refining furnace. 3. Ore-heating furnaces. 4. Resistance furnaces Advantage * Annual output of 80,000 tons, timely delivery; * Low resistivity * High temperature strength * Good thermal conductivity and electrical conductivity * Low thermal expansion coefficient * Low ash,Its ash content is controlled within 3%. * Dense and equal structure,Low graphite electrode consumption. * Good oxidation resistance * High mechanical strength * Needle coke content accounts for 80%, raw materials imported from Japan and South Korea |

| Lactoferrin | tartaric acid |

| L-theanine | Potassium hydrogen tartrate |

| Mixed Tocopherols Concentrate | Potassium tartrate sodium |

| Potassium Sorbate | malic acid |

| Sodium benzoate | Lactobacillus |

| gamma-Cyclodextrin | Benzoyl peroxide |

| Carmine | indigo blue powder |

| Amaranth | Stevioside |

| sodium bicarbonate | Sodium pyrosulfite |

| Ammonium bicarbonate | Sunset yellow food /Sunset yellow FCF |

| lemon yellow / tartrazine | titanium dioxide |

| Compound bentonite | taurine |

| Sodium cyclamate | Dehydroacetic acid |

| Citric acid | |

| Sodium tripolyphosphate | Alitame |

| Guar gum | Manganese gluconate |

| Diammonium carbonate | chitosan oligosaccharide lactate |

| monosodium glutamate | Sodium dehydroacetate |

| Glyceryl monostearate | beta-1 3-Glucan |

| Lipase | Sodium alginate |

| Nisin | Pancreatin / pancreatic enzyme |

| ARABINOGALACTAN | Sodium phytate |

| Xylitol | Gelatin |

Graphite electrode is mainly used in arc steel-making furnace, ore-smelting electric furnace, resistance furnace, etc., with good thermal conductivity, high temperature resistance, is widely used in metallurgy, machinery, electrical, chemical, textile, national defense and other industrial sectors. Graphite electrode is generally divided into ordinary power graphite electrode, high power graphite electrode and ultra high power graphite electrode.

| Category | No. | Specifications | |

| Diameter (mm) | Length (mm) | ||

| Ultra high power graphite electrode | 1 | 300 | 1800 |

| 2 | 350 | 1800 | |

| 3 | 400 | 2200 | |

| 4 | 450 | 1800 | |

| 5 | 500 | 2200 | |

| 6 | 550 | 2300 | |

| 7 | 600 | 2400 | |

| 8 | 700 | 2700 | |

| Technical Properties of Ultra High Power Graphite Electrodes and nipple | ||||||||

| Item | Classification | Unit | NominalDiameter (mm) | |||||

| 300-400 | 450-500 | 550-700 | ||||||

| Electric Resistivuty(<=) | Elatrode | μΩ.m | 6.2 | 6.2 | 6.3 | |||

| Nipple | 5.0 | 5.0 | 4.5 | |||||

| Bending strength(>=) | Elatrode | Mpa | 10.5 | 10.5 | 11.0 | |||

| Nipple | 18.0 | 18.0 | 20.0 | |||||

| Elastic moduluc(<=) | Elatrode | Gpa | 14.0 | 14.0 | 14.0 | |||

| Nipple | 18.0 | 18.0 | 22.0 | |||||

| Bulk density(>=) | Elatrode | g/cm3 | 1.66 | 1.66 | 1.66 | |||

| Nipple | 1.75 | 1.75 | 1.75 | |||||

| CTE(<=) | Elatrode | X10-6/ºC | 1.5 | 1.5 | 1.4 | |||

| Nipple | 1.4 | 1.4 | 1.2 | |||||

| Ash(<=) | % | 0.3 | 0.3 | 0.5 | ||||

| Note: Ash content and thermal expansion coefficient are parameter indicators | ||||||||

1.7 days delivery for small order(less than 80 Tons).

2.High quality products and strict testing.

3.Rich export experience.

4.We not only provide customers with pre-sales , but also after-sales services, so as to form strategic partnerships with customers. Company Profile

Q:What kind of products do you offer?

A:We offer Graphite Electrode(RP,HP,UHP),GPC,CPC,Graphite block,Isostatical graphite block,semi-finished graphite product and other graphite products.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is your terms of delivery?

A:We accept FOB, CFR, CIF, EXW, etc. You can choose the most convenient way for you.

Q:What is your Product packaging?

A:We are packed in wooden cases, or according to your requirements.