- Overview

- Specification

- Product Description

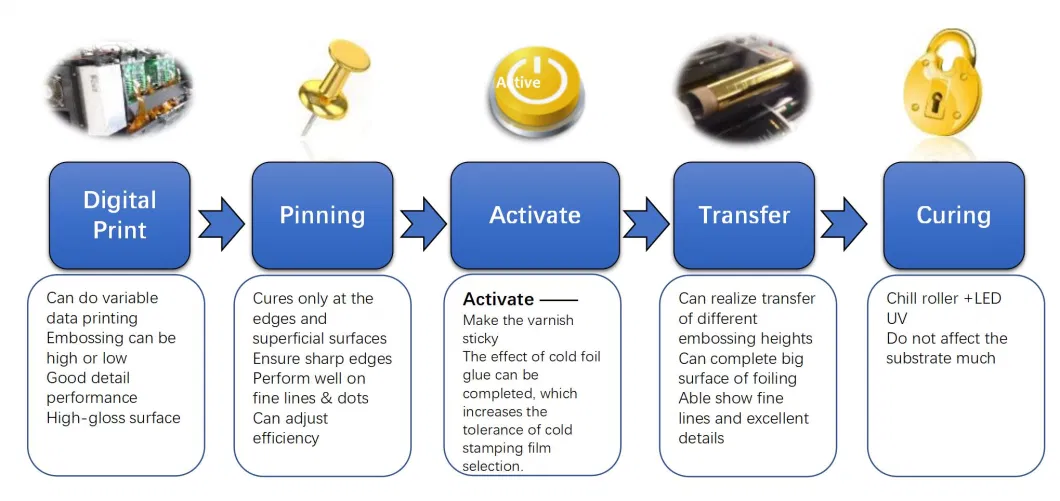

- DigiSpark Foiling Workflow

- Advantages Of DigiSpark

- Producing And Packaging

- FAQ

Basic Info.

Product Description

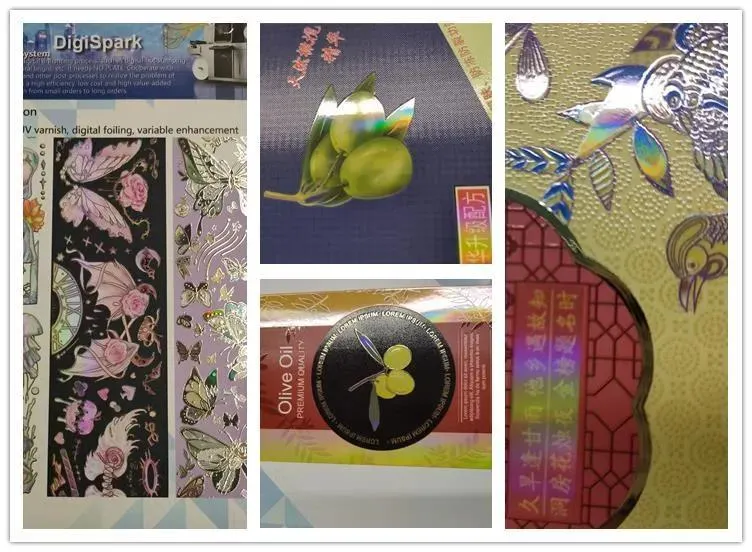

Digispark is a digital post-press effect enhancement machine.

It takes digital UV varnish ink-jet technology to achieve the varnish and foil staming 3D shinning effect.

| Model: DigiSpark | |

| Printing Technology | UV Piezo DoD(drop on demand)-inkjet |

| Resolution | up to 1440*360 dpi |

| Printing speed | Max. 60m/min(depend on polymer layer thickness) |

| Variable Image system | PDF, optimized PDF, Optional barcode system |

| Supported image standards | PDF,PDF/VT,TIFF, JPEG, BMP & other data base files |

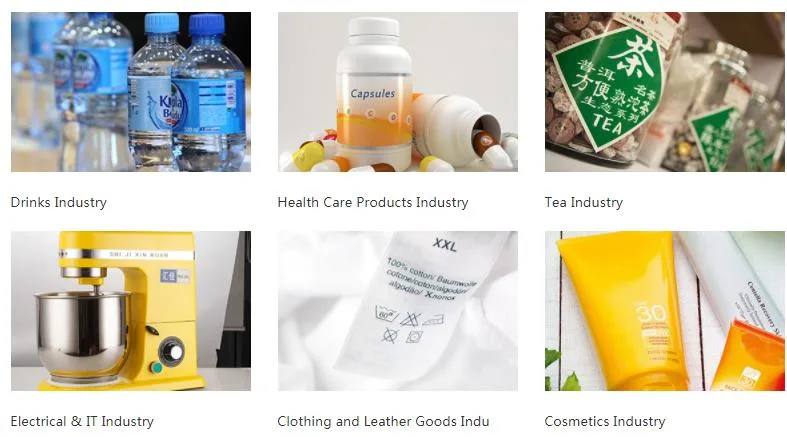

| Substrates | Offset, Digital, Plastics, Laminated and coated substrates |

| Printing image width | 288mm (extendable to 320 mm) * 10 m (Length) |

| Polymer | WB-DS-Clear Polymer |

| Polymer layer thickness | From 10 up to 200 microns |

| Ink curing | Inter UV-LED Pre-curing/Full curing by UV-LED |

| Unwinder diameter | Max. 700mm, Core 76mm |

| Rewinder diameter | Max. 700mm, Core 76mm |

| Substrates thickness | 30-400 micro |

| Substrates width | Max 330mm |

| Press with Foil station | Machine dimensions (LxHxW) 3500mmx1900mmx1800mm |

| Operating environment | Temperature: 15ºC-30ºC, Humidity: 40%-80% relative humidity |

| Electrical requirements | Voltage: 3x380, ±5% 3 phases +G+N ; Frequency: 50/60 Hz Current: Avg. 25 Amps |

| Weight | 2800kg |

Advantages:

-Low Cost -High Efficiency

-High Added Value And Rapid Completion Of Very Short To Medium Length Orders

Benefits of digital varnish inkjet printing:

1. High porductivity

- high speed and high productivity. Short production procedures, from computer to label.

2. The digital advantage

The digitalization of the spot UV finishing allows you to take a few sheets from each job and spot UV coat it, so your customers can see and feel the effect that their jobs could have. Your customer can 3D spot UV varnish on digital prints directly. Take advantage of the specially designed varnish formula coupled with the ability to precisely vary the thickness of coating thickness on each sheet to give your digital prints an individual and special touch. The thickness of the varnish can be adapted to the needs of the customer very flexible and on demand.

3. UV inkjet tecnology

The smart combination of the ink-jet technology with Drop-on-Demand Piezoelectric print heads, brings you the quality you deserve, from the first page to the very last.

High gloss embossed varnish

Inkjet printing technology + drop on demand technology to make varnishing area and thickness flexible embossing effect

Metallic effect by gold/silver foil stamping

Digital UV inkjet printing technology Variable foiling

Metallic effect by gold/silver foil stamping

Digital UV inkjet printing technology Variable foiling

1. What are the postpress effects achieved by this machine?

Cold foil stamping, varnishing, 3D shining and embossing.

2. Can this model do color printing?

No. it you need a hybrid label printing machine which can do both printing and postpress printing, you can consider our other models. Please consult our sales.

3. How about the lead time and payment term?

We need 45 days to produce this machine. Normally our payment term is 30% deposit and 60% balance before shipment and 10% after installation.

4. How about the installation and operation training?

Our senior will fly to your location to do installation and training. It takes about 2 weeks. The service is free of charge but we will need the buyer to take the round trip freight and local hotel and meal cost.

5. Can you visit your factory?

Yes, our sales center based in Hangzhou and our factory based in shanghai. You are warmly welcome to visit us.

6. Can you do the sample as we required?

Yes, we can sample your artwork on your specified printing substrate and then courier to you. and also shoted the printing procedure for your reference.

7. Is the machine printing white?

No. This is not a color printing machine. It is more like a varnish-jet postpress machine.

8. is the machine all digital? what are the other similar machines in the markets?

Yes, all postpress procedures are digital, without any blanket or flexo plate. Just similar to Domino, HP, Epson and screen related products. But much more affordable.