Basic Info.

Packaging & Delivery

Product Description

What Material Do You Want to Cut?

1. Use precision rotary die cutting technology and equipment to create any shape, including specific die cuts, cuts or perforations.

2. The die-cutting process is designed to achieve label output with small errors at a very high work rate.

Rolls loaded into a slitter rewinding machine go through programmed stages that convert the roll into smaller, narrower rolls. The master rolls enter a staging area before being loaded. Once loaded in the rewinding station, the machine cuts through the core's tails and tucks them into the core before unwinding and slitting the roll. Finally, the machine rewinds the rolls, seals the tails, and transfers the finished products to an exit conveyor.

Application:

Our Thermal Label Roll Die Cutter with slitting rewinding machine can cut any label on the market, such as: drug labels, food labels, wine labels, battery labels, outer box labels, shampoo labels, barcode labels, temporary labels for semi-finished products, etc.

Introduction:

LR350SD is a Thermal Label Roll Die Cutter, extremely efficient and precise for high volume of blank labels production. Each rewinder, unwinder and waste rewinder tensions are fully independent and adjustable in the HMI touch screen. Once the tension is set, there is no need for the operator to readjust the tensions. It is a sturdy machine combined with the latest high technology. Thermal Label Roll Die Cutter LR350SD has a very high work precision and produces excellent quality of finished rolls.

Advantage

HMI control and color display make operation easier. The new future-proof industrial control system enables modern alarm management, remote maintenance and diagnostics.

Servo drive technology increases process stability and increases production downtime: the system runs more smoothly, and the starting and braking speeds can be set independently. The new die cutter also allows the machine to be restarted immediately, while the material can remain in the machine.

Modern job management reduces changeover time from 30 minutes to 15 minutes thanks to automatic presets.

Features

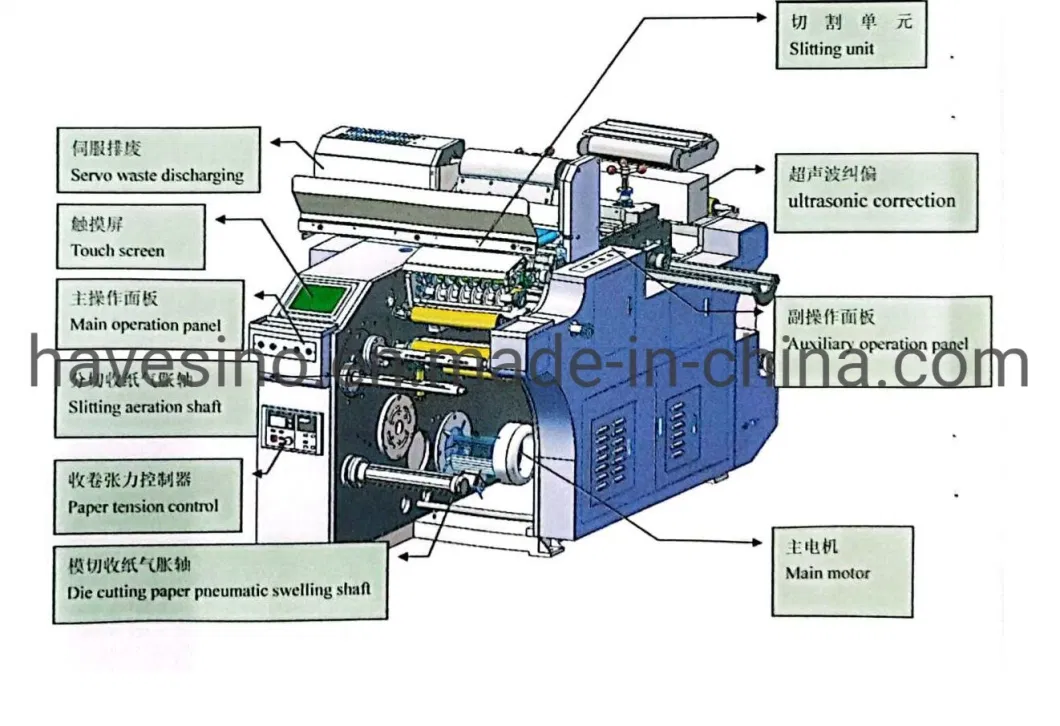

-UNWINDER & WEB GUIDING

This section contains a self-contained motor-driven unwinder with closed loop tension control, electronic web, 76 mm air expansion mandrel and maximum diameter 780 mm roll capacity.

-VISUAL TABLE

Moveable visual splicing table with a two-sided clamp pressure bar.

-SLITTER

Shear slitters or blade slitters are available, which are easy to install and have a standard high pressure waste extraction system.

-REWINDER

The winder adopts a closed-loop tension control system to ensure continuous and stable tension. The maximum rewind diameter is 630 mm.

Specification:

| Slitting speed | 150m/min |

| Max Paper Feeding Width | 100-350mm |

| Min Die Cutting Width | 15mm |

| Max Unreeling Diameter | 800mm |

| Max Die Cutting Reeling Diameter | 630mm |

| Waste Discharge Type | Scraper Type |

| Dimension | 2550*1500*1700mm |

| Motor Total Power Input | 3KW |

| Main Motor Power Input | 2.2KW |

| Power Voltage | 380V |

| Compressed Air | 0.6MPa |

| Weight | 1500KG |

HAVESINO Group is a R&D and Manufacturer of Slitter Rewinder and Converting Machinery for the worldwide Packaging and Label industry over 12 years.There are in excess of 800 of machine installations worldwide!

HAVESINO's primary goal is to build economic machines that operators find easy to use, and maintenance personnel find easy to maintain. We believe that our customer's prosperity is directly related to our success. That's why, in all aspects of our operation, every effort is made to achieve nothing less than your total satisfaction.

Today,HAVESINO's focus is on designing,manufacturing and servicing the highest quality slitter rewinders and other auto machinery in the world. Selling the machine is not the end of the deal! Our faith is that a sale is never final without a commitment to service.

FAQ

Q.:Are you a factory or trading company?

A.: We are a factory and manufacturer.

Q.:How does your factory do regarding qaulity control?

A.:We pay much attention on quality controlling from very beginning to the very end. Fully check and test takes before shipment.

Q.:Where is your factory located? How can I visit there?

A.:Our factory located at Hangzhou,China.You can fly to Hangzhou air port directly or take fast train from Shanghai.We will arrange to pick you up from train station or airport.

Q.:What's service or guarantee can you offer?

A.: One year guarantee for key parts of machine;Machine installing and worker training service;Free technical support whole life;Material support.